Product Description

ISX15 QSX15 diesel engine FAN DRIVE 12PK V RIBBED BELT 3106099

| Part Number | 3106099 |

| Part Name | Belt |

| Brand Name | |

| Engine Family | QSX15 ISX15 |

| Warranty | 6 Months |

| Packing | Original Customized |

| MOQ | 1 PCS |

| 1 | Temperature Sensor Genuine | 4957112 |

| 2 | Pressure Temperature Sensor | 2897333 |

| 3 | Temperature Sensor | 4 0571 32 |

| 4 | Position Sensor | 4921684 |

| 5 | Mass Flow Sensor Genuine | 4984760 |

| 6 | Pressure Sensor Genuine | 3974092 |

| 7 | Pressure Sensor .Oil | 4921487 |

| 8 | Temperature Sensor | 357185 |

| 9 | PRESSURE SENSOR | 3084521 |

| 10 | Pressure Temperature Sensor | 4921483 |

| 11 | Pressure Temperature Sensor | 4921473 |

| 12 | Position Sensor | 4921599 |

| 13 | Temperature Sensor | 4954905 |

| 14 | Coolant Level Switch | 4383932 |

| 15 | Engine Speed Sensor | 3971994 |

| 16 | Sensor, Prs Temperature | 4921493 |

| 17 | Position Sensor | 4921599 |

| 18 | Pressure Sensor | 4928594 |

| 19 | Position Sensor | 4921601 |

| 20 | Position Sensor | 4921597 |

| 21 | Air Pressure Sensor | 3682610 |

| 22 | Fuel Pump Solenoid 12V | 3935649 |

| 23 | Fuel Pump Solenoid 12V | 3906398 |

| 24 | Fuel Pump Solenoid 24V | 3864274 |

| 25 | Fuel Pump Solenoid 24V | 3977620 |

| 26 | Temperature Sensor | 3967250 |

| 1 | 3288889 | 3289246 | 3289779 | |||

| 2 | 32889 | |||||

| 3 | 3288911 | 3289268 | 3289842 | 3911569 | ||

| 4 | 3288922 | 3289314 | 3289864 | 3288497 5255304 | 3289897 8PK2155 | 5262264 |

| 5 | 3288933 | 3289325 | 3289897 | 3934964 3805909 | 5262265 8pk2120.9 | 4993970 |

| 6 | 3288944 | 3289369 | 3289930 | 3911620 3289179 | 8PK1980 1308BF11-030 | 4930899 |

| 7 | 3288955 | 3289404 | 3289941 | 489 | 3288689 329 | 3288724 |

| 8 | 3288999 | 3289437 | 3289985 | 3974030 5256363 | 3911588 3908037 3288757 | 4982924 |

| 9 | 3289 | 3911558 3288867 385716 | ||||

| 10 | 3289012 | 3289481 | 329571 | 217638 3019406 | 3288856 3925953 3921603 | |

| 11 | 3289056 | 3289492 | 329 | 3288746 3921753 8PK1440 | ||

| 12 | 3289089 | 3289514 | 3290121 | 8PK1425 3911588 | 3911562 3903092 3939580 3288812 | |

| 13 | 3289102 | 3289547 | 3290142 | |||

| 14 | 3289113 | 3289558 | 3290151 | |||

| 15 | 3289135 | 3289582 | 3290158 | |||

| 16 | 3289146 | 3289593 | 3325963 | |||

| 17 | 3289157 | 3289648 | 3401283 | |||

| 18 | 3289179 | 3289659 | 3626788 | |||

| 19 | 3289213 | 3289697 | 3629256 | |||

| 20 | 3289224 | 3289746 | 3644379 | |||

| 21 | 3289235 | 3289768 | 3681636 |

1 7571 Dowel, Pin

2 2868740 Hub, Fan

3 142176 Nut, Lock

5 2868735 Pulley, Fan

6 3012467 Washer, Plain

7 3063844 Cover, Fan Hub

8 3081164 Bearing, Roller

9 3681705 Spindle, Fan

10 3026269 Washer, Plain

11 357136 Screw, Hex Flange Head Cap

12 357139 Screw, Hex Flange Head Cap

13 357140 Screw, Hex Flange Head Cap

14 3106099 Belt, V Ribbed

15 315711 Tensioner, Belt

16 3681129 Support, Fan

17 3681130 Bracket, Fan

18 3681587 Pulley, Idler

19 3681715 Adapter, Pilot

20 3957160 Screw, Hex Flange Head Cap

21 395712 Screw, Hex Flange Head Cap

22 3914407 Screw, Hex Flange Head Cap

23 3935013 Shield, Dust 1

HangZhou CZPT Industry & Trade Co., Ltd.

Add:Haili Industry Park ,HangZhou Economic Development Zone ,ZheJiang ,China Post Code:442013

engine

What to Look for in a Belt Tensioner

If you notice the power steering, air conditioning, or power steering stops working, chances are that your belt tensioner has been compromised. A compromised belt tensioner can be completely destroyed overnight, or it can last for a long time before it breaks. Either way, you should never drive with a faulty belt tensioner. It’s far better to have it replaced before the engine shuts down completely. In addition, replacing a belt tensioner will prevent other complications, such as power steering or air conditioning, from occurring.

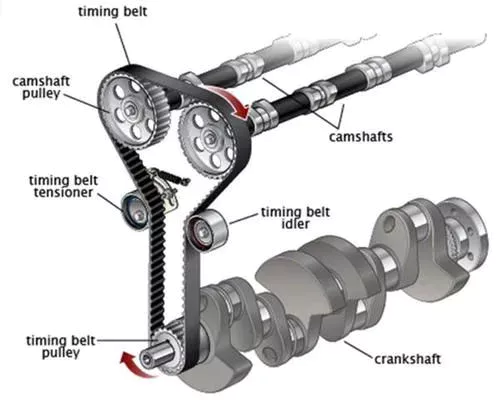

Misaligned idler pulley

If the tensioner arm is not rotating freely or has an abnormal chirping noise, it could be the result of a misaligned idler pulley. If this is the case, replace the idler. If the idler does not move, you may need to adjust the accessory mount points or use a laser alignment tool. The tensioner arm is only 1 part of the tensioner.

A misaligned idler pulley on a belt tensioner is usually the cause of a squeaking noise. If this noise continues even after a replacement of the belt, it’s time to replace the whole belt. A misaligned idler pulley can also be the cause of premature belt wear. If the idler pulley is out of alignment, it could also cause the belt to wear too fast and lead to the premature failure of the timing belt.

The tensioner pulley is made of nylon, steel, or plastic. It may be flat or grooved. Before replacing it, check for any cracks, dents, or debris on the pulley’s surface. Plastic pulleys may have broken sidewalls. If the idler pulley is worn out, you might also notice squealing noises when the vehicle is in motion.

The misalignment of a belt is most pronounced when the span between the 2 pulleys is short. When the span is long, however, diagnosing the problem becomes more complicated. Small degrees of offset may not be visible to the naked eye, but a laser alignment tool can help identify these subtle variations. In order to identify a misaligned idler pulley on a belt tensioner, you must first determine its cause.

When the tensioner’s idler pulleys are out of line, a belt tensioner will not be able to properly adjust the torque that the belt is under. This may result in squealing noises. If this is the case, it is time to call a mechanic. He or she will be able to determine the cause and correct it. If you suspect the problem, your next step is to replace the idler pulley on the belt tensioner.

If the ribbed belt is not properly aligned, you may have a misaligned idler pulley. To fix the misalignment, locate the belt adjustment bolt underneath the hood. You should be careful not to damage the alternator or battery terminal while doing this task. If you do accidentally connect the battery positive to the earth, you might be able to damage the ribbed belt and ruin your vehicle’s timing.

Besides a misaligned idler pulley on the belt tensioner, another problem may be the alternator’s serpentine belt. If your car’s alternator belt is not aligned properly, you could have misaligned the alternator’s pulley or a worn-out bearing. Regardless of the cause of your problem, you should have the belt inspected.

Bad idler pulley

Having a Bad Idler Pulley on a Belt Tensioner? If this sounds familiar, then it’s probably time to change it. Idler pulleys slowly take hits while the engine is running, causing the belt to wrap and bend. Eventually, the belt will slip, and a new idler pulley should be installed to ensure optimal tension. But before you spend a dime on a new one, let’s talk about what to look for.

Symptoms of a Bad Idler Pulley: If the noise persists, there is a problem with the idler pulley or its bearing. These parts wear out over time and may eventually cause a cracked idler pulley or serpentine belt. Not only will the idler pulley create an irritating noise, but it will also damage the belt itself, leading to overheating, stalled engine, and even damage the head gaskets. Thankfully, a Bad Idler Pulley on a Belt Tensioner is easily replaced and will only cost about $40.

Although the Idler Pulley is not the most popular component on a car, it’s a critical part that ensures that the engine runs smoothly. It’s easy to overlook this part, but its failure can make it impossible for your vehicle to operate at its optimal level. Moreover, a Bad Idler Pulley on a Belt Tensioner will cause your engine to malfunction, so it’s essential that you check it at regular intervals.

If you notice a squealing noise while driving, the Idler Pulley is likely the culprit. Because of friction between the engine belt and idler pulley, the engine belt rubs against the pulley, causing it to squeak and make a clicking noise. This squealing noise will continue until the problem is repaired or replaced. It’s time to start addressing the problem before it becomes too late.

If you notice the tensioner pulley moving away from the engine, it’s most likely that the pulley is malfunctioning. A belt that is loose or slack may make it difficult to start the car, or your engine may even overheat. If this occurs, it’s crucial to replace the Idler Pulley as soon as possible, because a Bad Idler Pulley on a Belt Tensioner can seriously damage your vehicle.

The Idler Pulley facilitates the motion of the engine belt. It serves as a smooth rotating point that allows the belt to loop without a barrier. Over time, this part of the system will begin to show signs of wear and tear, and replacement is vital to protect your engine, serpentine belt, and other accessories. An early warning sign of a problem is a squealing sound coming from the engine area.

Broken tensioner arm

The belt tensioner is a piece of machinery that is used to keep the belt tight. If this part breaks, you can easily repair it yourself using a long-handled ratchet, serpentine belt tool, or a socket. To repair the tensioner, simply remove the drive belt from the pulley and rotate it to release tension. Check for roughness, resistance, or binding of the drive belt.

Noises caused by the tensioner are a sign of a damaged component or excessive oscillation. These noises are usually caused by worn internal components or the tensioner’s pivot bushing. In some cases, the vibration damping system or a worn-out alternator pulley could also be to blame. If this is the case, replace the pulley and tensioner together. To check the condition of your belt tensioner, follow these steps.

In addition to worn-out springs, a loose or broken pivot arm could be causing your belt to misalign. A worn-out tensioner pulley bushing will also cause vibrations, noise, and seizing. Lastly, a broken tensioner spring could be preventing the belt from maintaining proper tension. Broken springs are also prone to loss of tension due to heat. Damaged tensioner housing can also affect belt tension.

Once the belt is installed, you need to check the condition of the pulley and the tensioner arm. Make sure that the pulley is moving and that the arm is moving smoothly with the cranking and releasing. If the arm is wobbling, the tensioner is failing. If the pulley wobbles or excessive chattering occurs, the tensioner is failing. It can also be seized or jammed.

If the tensioner arm has broken, replace it. Replacing the tensioner can be a tedious task. Be sure to use a suitable tool to tighten the pulley and tensioner. If you are not sure of how to replace the pulley, try using a serp belt tool. Another good option is to purchase a 3/8 drive ratchet. If you don’t have this tool, you can use a long 3/8 extension and a deep socket.

The belt tensioner assembly can fall off the engine, causing damage to the timing belt. If you are replacing it, you must replace it with a new one, and tighten all of the mounting bolts before reinstalling it. To avoid further damage to the engine, ensure you replace the belt with a new tensioner and a new belt. The tensioner is bolted to the engine’s timing cover, so make sure you carefully tighten the bolts when replacing it.